|

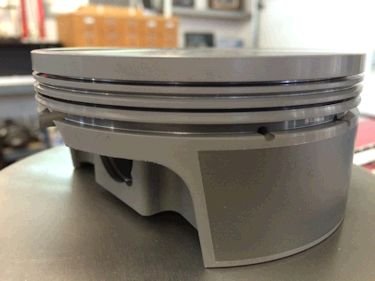

The new Mahle power pack with 1/1/2mm piston rings. This is

for a 3.875" stroke. Part # 930200830

|

408 grams

|

|

Dramatically thinner than most ring packs. The rings are 22.5g and

the oil rail is 5g

|

554.2g piston-pin-rings-loc-rail

|

|

Compstar 6" rods =

448/174g, King rod bearings = 38g, Bobweight = 1705g

|

Block freshly honed.

|

|

Callies Dragonslayer crankshaft cleaned and ready for journal

sizing.

|

|

|

Rods are 2.0990 and Mains are 2.4480

|

Rear main at .0031" with .001/.001" mix, (even though it

shows .0027 here)

|

|

|

|

|

6" Callies Compstar rods assembled to the Mahle pistons.

|

Here is my new bore gauge in size 4.030"

|

|

|

Ring gaps are .021"/.021"

|

|

|

|

|

Cam bearings installed after the block received it's final soap

and water cleaning.

|

Rear main oil hole made to transition into the bearing as smooth

as possible.

|

|

|

Thrust is .007"

|

|

|

|

|

|

The crankshaft is installed and it spins

freely. The piston ring gap was spot checked in the cylinder

bore to be .021/.021 (+ or - .001).

|

|

Trying to get a close up photo of the 1mm rings. Very light

weight and flexible.

|

King rod bearings. Mix of standard and .001

|

|

.0023"

|

#1 piston installed.

|

|

Piston is .008" in the hole. I have the block decked to

about 9.010" on purpose to help with intake manifold fitment.

|

I need to do more block clearance work

due to the rod hitting the cam side of the cylinder bottom. The

3.857" stroke needs a lot more block work than the 3.75"

(383).

|

|

Clearance and clean.

|

All pistons and rods installed. I had to do new cam bearings

because I took out the previously installed cam bearings to do the

cleaning. (the old set is still in ok shape but are technically a

blemish set now. I will use them in one of my personal

motors.

|

|

Rod side clearance .019"

|

|

|

|

Jeff Johnston oil pan requires an oil pump pickup aligned near the

rear of the pan. One is on order, (custom) from Stef's.

|

|

The pickup that I ordered from Melling is not going to fit.

|

Crower shaft rockers mocked up and pushrod length checked.

These are 8.000" and a bit too short. 8.150" or on

order.

|

|

.745/.748" lift with .020" lash.

(.450/.451" lobe and 1.7:1 rockers)

|

The rockers tips fit directly on center of the valve tip but just

a tad off-center to the rear of the motor. (this is common).

|

|

I tried to get a shot of the open exhaust valve.

|

|

|

New holes machined on the head for the Edelbrock manifold

|

Manifold mocked up nicely. Bolts went in easily. That

never happens.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Crower stainless steel shaft rockers. (1.7 ratio, .150"

offest)

|

|

|

Pushrods tested for length. I ordered 8.150" but

8.100" would fit better. Back to the credit card for

another set of pushrods.

|

Valve train fully mocked up with lash at .010" cold.

All seems to be working nicely. Head bolts not all in yet so

that I can do a piston to valve clearance check.

|

|

|

New custom made oil pump pickup from Stef's.

|

|

8.100" long by 3/8" wide pushrods installed.

|

Lash set at .010" cold. (should be .020" hot).

|

|

View of the additional bolt holes for the Gen-1 intake manifold.

Machined by Advanced Induction.

|

Heads with the 2 extra bolt holes for the intake manifold.

|

|

Here is the modification to the intake manifold.

|

Comp mechanical roller lifters.

|

|

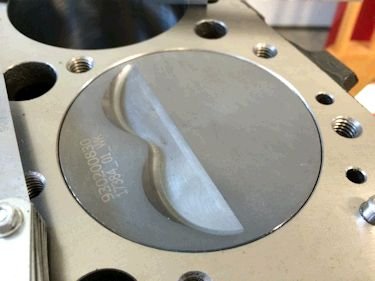

Last look at the CNC porting of the intake runners.

|

The intake manifold gasket needs to have holes punched for the new

bolt holes.

|

|

The intake manifold has a large gap at the front and back end so

the RTV bead needs to be thick.

|

Waiting for the RTV to set.

|

|

No RTV on the oil pan gasket. Hoping that it seals well

enough. It's nice to be able to pull the pan and inspect the

bottom without having to deal with RTV.

|

|

|

|

|

|

Setting up at Jim Morgan Racing Engines dyno

|

|

|

Still using my Impala SS expansion tank

|

|

|

|

|

|

|

|