|

I like this steam line set up and took a photo for duplicating this

set up in my car.

|

Some of the exhaust ports looked like this. Not all of them.

|

|

5 seconds after removing the intake manifold.

|

|

|

|

|

|

|

|

|

|

|

|

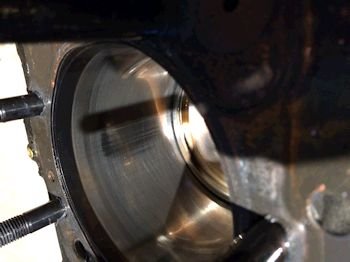

To my eye the bores do not look all too bad.

|

|

|

Some side loading of the pistons. (not fuel wash)

|

The block bores are not able to stay perfectly round but I think

the rings can conform to the out-of-round.

|

|

|

The bores were oval and had to go to 4.0320" to make round.

|

|

New and stronger Manley Nextek 221435 springs, 23615TS-16 retainers,

13194-16 10* locks

|

The valve stem seals were found to be loose and off the boss.

The as-found seal was ELY/322-1010 Viton blue. The new seal

fits tighter on the boss and is PBR brand 500-11/32

|

|

The heads showed signs of valve float by valve spring lock chatter

marks. The seals may have rattled off the valve guide boss.

|

This is the seal that fits not so tight on the boss.

|

|

Obtaining weight values for Callies balance shop.

|

Piston 475g

|

|

Brian wanted a lot of photos

|

This Diamond custom piston is 1.280" CH for a 4.0320"

bore.

|

|

"Double-Diamond" hard anodized and slip skirt coating.

|

Secondary machining on the ring lands after anodizing.

Double pin oiler, milled under the crown for weight savings.

|

|

Did we overdo it on the massive pin?

|

Saved a few grams on the locs :)

|

|

I use a 3-beam scale.....

|

And a digital scale as a back-up.

|

|

New Crower hydraulic lifters

|

Piston to wall is .0065"

|

|

Cam bolts torqued to 20ft-lb

|

Ring filing: .030" 1st and .030" 2nd

|

|

|

|

|

|

|

|

|

|

|

|

Green bores?

|

|

Decided to use Total Seal "Quick-Seat"

|

|

|

Crankshaft has returned from Callies and it is balanced at 1825g

bob-weight

|

Re-used the Clevite bearings

|

|

Crank sets in place nicely

|

Same photo...LOL

|

|

Thrust at .008"

|

|

|

New lifters require longer pushrod.

|

7.2 and 7.5"

|

|

Compstar 5.850" (hopefully less side loading compared to

5.7" rod)

|

Each rod journal is still at 2.0990"

|

|

Standard size HN bearings give .0020 to.0023"

|

Ready to install piston-rod combo #1

|

|

|

Piston at zero

|

|

|

#2 rod and piston combo?

|

|

oops. It was really #3

|

Some bare spots getting a touch up

|

|

|

|

|

.005" rod bolt stretch and .020" side clearance.

|

|

|

One head stud had damage on the threads and is getting

replace. (could not fix by chasing it)

|

New lifters get a bit of soaking

|

|

Installing lifters NOW!

|

|

|

Cometic .040" head gasket

|

|

|

Heads on and stud nuts torqued to 80ft-lb with oil

|

This is why the lifters go in before the heads.

|

|

All rockers aligned on valve tips

|

ISKY adjustable guide plates

|

|

New crank seal custom ordered for BBC crank nose and TPIS timing

cover

|

|

|

I viewed the 24x reluctor through the crank sensor hole to

verify that the hub is fully seated.

|

LT1 dynamometer intake manifold mocked up.

|

|

Still need rear main seal housing gasket when the parts stores

open.

|

Still need to pump up the oil and test the new lifters and

verify oil pressure.

|

|

Pressure test looks good.

|

All lifters pushed oil up into the rockers.

|

|

|

Temporary timing pointer set up for engine dyno.

|

|

|

|