|

|

|

|

|

|

Nice rockers and clean intake valley.

|

|

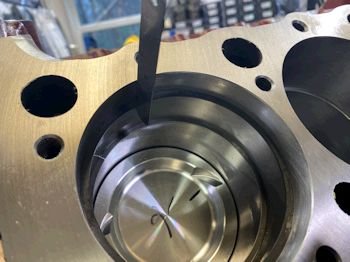

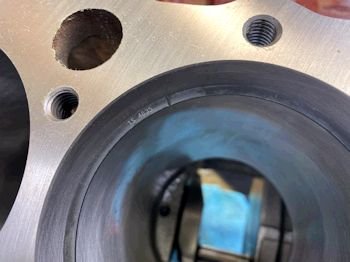

Both heads have detonation pitting

|

This can be surfaced and fixed. Dennis Staff of Fast Cat

will refurbish the heads and design a new camshaft. |

|

|

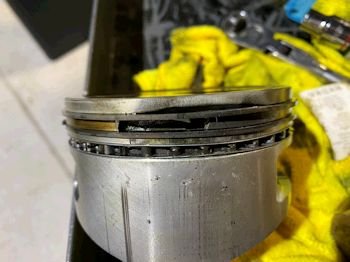

Most of the pistons look like this.

|

Too much boost/cylinder pressure. |

Nice Callies crankshaft

|

One cam plate bolt head stripped. |

Main bearings look nice.

|

Block is back from the machine shop and splayed main caps were

added. |

New custom blower pistons from Diamond.

|

|

|

Bob weight calculated 1789.5g

Neutral

Crankshaft is at the balance shop. It may need heavy metal

added due to the new piston being heavy and the new H-13 tool

steel wrist pin being extra extra heavy. |

Assembly time.

|

The crankshaft journals were polished at the balance shop |

#5 Main is 2.4489"

|

X and standard mix King XP bearings. Shooting for .0025

to .0030" bearing clearance. |

Later I'll grind the oil hole to match the bearing.

|

Here is an additional clearance area that I added just prior

to doing the final block cleaning. Some head gaskets require

this area to be clearanced for oil drain back. |

Making sure I installed the oil galley steel ball.

|

Cam bearings going in. |

|

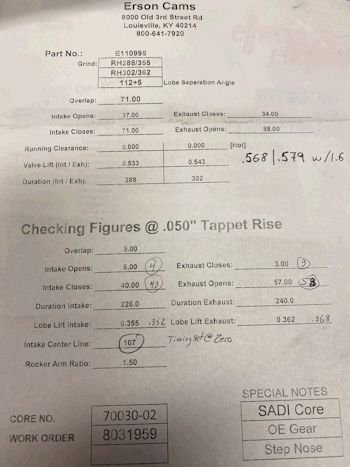

Camshaft from Dennis Staff:

226/240 duration .568" lift blower cam. |

Front oil galley plugs installed.

|

|

Crank thrust is .005"

|

Crank installed and main caps all torqued. |

Old stock water pump drive gear on the left and new gear

installed on the shaft to the right.

|

My goal is to install the timing set so that I can have the

cam rotating along with the crank/rods/pistons in order to know if

there will be interference between rod shoulders and cam

lobes. The engine is getting this new Cloyes timing set to

replace the stock timing set. The water pump gear is not

exactly the same tooth cut as the stock gear and so it gets

installed on the stock water pump drive. |

Now installing #1 rod and piston combo. This is so that I

can degree the camshaft.

|

Looking for top dead center. |

Not on camera but the cam degreed perfect at 107 intake

centerline. This is with the timing set sprockets at

"0"

|

|

Installing the rest of the rods/pistons. Here is #5 rod on

the left and #6 rod on the right. Both gave me a surprise in

that they had collected melted aluminum from the torch effect during

the engine damage event. At first I thought they were burnt

and then would be brittle and or distorted or unusable. Then

after careful inspection the blasted-on aluminum could be removed by

my wire wheel and the piston wrist pin fits perfectly and the rods

seem to be in perfect shape.

|

#5 on top and #6 below, (after cleaning). |

See the extra sturdy piston wrist pin? That was ordered as

an upgrade.

|

|

|

|

Not really custom but Diamond can get ring sets for their

customers from Total Seal. I have used the 1.2mm ring pack for

many engines.

|

Good quality and big money. |

I gapped for 15 psi or more forced induction. A bit more

gap than recommended. .026" 1st ring and .026"

2nd.

|

Photo of a lone piston ring. This is #5 piston 2nd

ring. It came from my spare parts bin. The ring that

came in the piston kit set did not fit quite right when I

installed it on #5 piston 2nd ring groove. It would not spin

freely. I was very careful not to bend the ring but possibly

I did bend it. Or it was bent from the factory. Who

knows but I am lucky to have 2 packs of this ring size as a spare. |

Here is that brand new ring and I cannot see any damage but it

does not fit well in the groove. The replacement ring does fit

well.

|

|

|

No forgetting the thread locker for the cam bolts and the

torque to 25 ft-lb. |

|

The rod bolts to the left show

.0045" stretch after torque to 70 ft-lb.

Believe it or not all of the rod bearings checked out to be

.0027" using a standard size set of King CR807XPN. |

|

Short block fully

assembled. More assembly in the next few days. Stay

tuned. |

So: I had the heads on and realized that the compression

ratio was not where the owner wanted it. I ordered a new set

of Diamond custom pistons to bring the compression ratio up to

9.4:1

|

Heads back off. |

Oil pan off.

|

|

|

Old pistons out. Still "New" but they have too

much dish and give 8.7:1 compression ratio. The new pistons

are there sitting on the AFR cylinder heads. Now we will

have 9.4:1. I've had the pistons for quite a long

time. Just been swamped with my power plant job and a home

improvement (prepper) job.... |

There is my tuning buddy Zach who came over today to help me

organize the shop. This Solar installation had me pile up a

lot of stuff in the engine building room which gave me no inspiration

to build engines. Now I'll be methodically working my way

through the engine build backlog.

|

|