The Cola crankshaft was polished (very nicely I might

say). Also the balance was checked.

|

I reused every main bearing due to the bearings being in

perfect shape. Saves money. |

I've got .0025 to .0030" clearance with the mix of X and

standard bearings.

|

Reusing the old pistons but using new Wiseco piston rings.

These are spec'ed for this set of pistons. 1/16" /

1/16" 3/16". |

I'm going .026" / .026" on the ring gap.

|

|

|

Installing cam bearings |

|

New cam pin. Not too long, (not too short). |

Oil galley ball verified installed for my records.

|

Crank thrust at .0035" |

Crankshaft in and mains torqued, (studs at 80 ft-lb and bolts at

65 ft-lb).

|

The oil pump mounting stud I used may have been a tad too

long. I noticed it bottomed out on the bearing. This stud in

the package is from ARP. I'll use the ARP stud. |

Rods 1, 3, 5, 7 all exactly 0.0025" clearance and all

original bearings reused.

|

I noticed #6 rod has the bushing smashed. I could not

fix that. It was sort of fused into the rod metal. |

The other 1/2 of the rod has a smashed area to receive the smashed

bushing material.

|

Sine this rod had great bearing wear I will leave it as is. |

It seats well even with the bushing problem.

|

|

Rotating assembly installed. Still need to degree check

the cam shaft.

|

While there is access I decided to install the rear main seal

housing. These are .003" feeler gauges acting as shims

to align the rear main seal housing. |

Then I use the old rear seal as a guide to hammer on the new seal.

|

|

Rod bolts torqued to 75 ft-lb. The rod side clearance is

.022". (previously I have written down that it was .020")

|

Reusing stock oil pump with Jeg's retainer. |

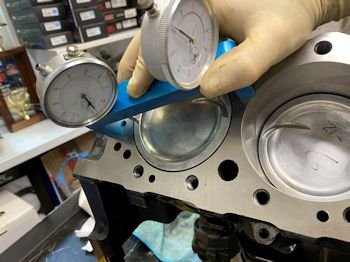

The block was honed for a fresh round bore. It is now at

4.035" That is good and loose for a blower motor.

Piston to bore is .009"

|

Pistons are .012" in the hole. Interesting that I

had measured them to be .008" in the hole during the initial

build. My measuring technique must be more refined now. |

Oil galleys behind the timing set are plugged.

|

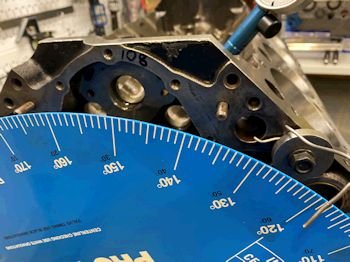

Right now the double roller timing set is being reused.

It is in good shape. I have the crank sprocket at the +4 and

the cam is at 108* intake centerline which is right at the cam

card spec. |

|

|

Now tackling the used 1st generation 24x kit from EFI

Connection. The cam pin from the previous owner was too long

and gouged into the cam sensor housing. That's not a fatal

flaw. Just pointing that out. This is the front side of the

housing and the cam sensor would fit in here. I made sure the

poked metal was flat.

|

Then I made a blunder by not checking fitment carefully.

The crank sprocket for the 24x will jam into the crank seal lip

inside the timing cover, (if you use a double roller timing

set). This 24x previously owned sprocket was for a stock

single roller apparently. I busted the timing cover when

torquing the bolts to 12 ft-lb. Will address that in a few

days after some parts from EFI Connection arrive. |

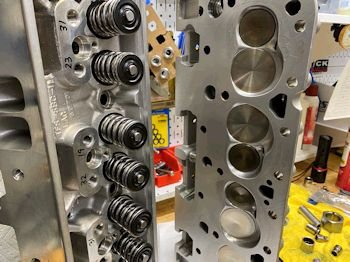

Refurbished TFS 21* cylinder heads.

|

Dennis Staff of Fast-Cat Porting Service honed the valve

guides and did a valve job. Also cut the valve guides for

.500" tall valve seals and installed springs to spec.

The heads had the deck milled slightly for a clean-up. The

intake valve springs are at

1.720" - 178lb closed

1.155" - 404lb open

Coil bind is 1.050" so there is .102" clearance.

The exhaust springs are similar. |

Check of combustion chamber volume.

|

54cc |

Heads on with Cometic MLS head gaskets .027" thick.

ARP head bolts (re-used) at 70 ft-lb.

|

The pushrod guides do not line up the rocker tips. |

Flipped the pushrod guides upside down and now they work.

|

7.300" pushrod being reused. It looks to work well. |

EFI Connection double roller timing set and crank reluctor

|

|

Re-doing the cam degree check. I started off with the

sprocket at the advance 2 deg position. Had to find top dead

center with the heads on. LT1 spark plug holes don't angle

such that a normal pistons stop tool works.

Photo to the right shows my new and favorite method for a piston

stop. This long 3/8" drive extension goes all the way in

the #1 spark plug hole and to the far cylinder wall. Then the

piston comes up and gently touches...mark the spot...do it again the

other way....etc. etc. I push the piston stop tool (extension)

all the way to the far side of the bore in order to be

consistent.

With the new timing set at +2

then the cam intake centerline was exact 108 deg. (exact as

cam card).

|

|

|

24x reluctor on before the timing cover. |

Used timing cover. Previously had the cam pin too

long. Just showing all the blemishes now before I put the

cover on.

|

|

Look at that. Perfectly centered.

|

Cam sensor. |

|

|

|

|

I noticed the crank bolt was broken way back when I took it

out. Then forgot all about it. The other part is

probably in the crank nose. There is plenty of thread area

still available in the crank nose.

|

I'm donating a new crank bolt. I checked and this will

thread all the way in and not bottom out on the remnant bolt

piece. |

|

Crank bolt in and torqued to 90 ft-lb. I used 2 washer

to space it out. |

|

I see the slight wear in the oil pump drive gear.

Thought I would replace the gear but then noticed the replacement

is just an iron gear. This current one looks to be an even

better quality. Since it is only slightly worn I think it

would be best to re-use the old gear. |

|

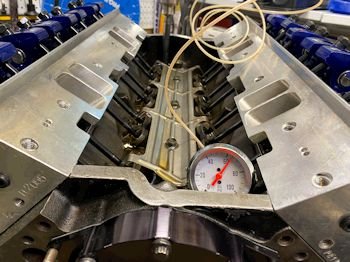

65 psig drill pressure test. |

|

I stopped here for the day. The lifters all pumped up

oil quickly except 2 of them. The associated pushrod was

slightly out of the lifter seat. I tried re-adjusting and

they both went out of the seat again. Then I tried 2 new

Crower lifters (stock style) and the Crowers would not pass oil

after 15 min of drill spinning. Now it's time to think

and investigate further. |

GMPP LS1 lifters. I suspect that these are made by Johnson

Lifters. Part number GM 88958689. $383 at Summit

Racing. A good reliable and affordable lifter is hard to find

now-a-days.

|

I don't have a Johnson lifter to compare this to but it looks

like a Johnson (except for the bow tie logo). |

Crower stock style (in wrapper), Comp in middle, GMPP on right.

|

Lifters all installed and pressurized with oil. They

take a long time to send oil up to the pushrod and that is typical

of the high performance slow bleed lifters. |

Dyno intake gasket (not-new). After the dyno session the

engine will receive a new gasket.

|

Temporary timing pointer installed and verified to be exact

top dead center. |

|

Dyno session scheduled for

Monday August 23rd.

It did not go well. I don't think the rings seated

well. Going to re-balance and get Mahle pistons

4.040". Block will get a bore and hone to 4.040" |

Little known fact that Mahle will have any piston coated if you

ask. Cost a bit more but may be worth it for some

applications. This is a -26cc dish and a 4.040" piston.

|

I and bummed out here. There are oil puddles in every

cylinder. |

|

Disassembly of engine so that I can get the crankshaft to the

balance shop. |

|

|

Bearings look great!

|

|

|

New piston and one rod and the

bearings and the rings/pin/locks all go to the balance shop.

The block goes to the machine shop too for a bore to 4.040" |