The block has been fully machined prior to arrival at my

shop. It has a lot of anti-rust wax on it.

|

Now just have to give the block a good cleaning. |

I started with WD40

|

Then figured I would take out the cam bearings to get all the

nooks and cranies. |

Hot pressure wash

|

Oil soaking with more WD40 |

|

|

I put one piston in to verify that it's the right size and I

also measured piston to bore to be .004"

|

Prior to installing the cam bearings I'm going to mock up the

rotating assembly. The main bearings are installed

temporarily so that I can install the crank. This King

bearing will need to have the oil hole widened. |

The crankshaft is from Callies. This is a full Compstar

kit. Mahle pistons, Compstar crank, Compstar H-beam rods,

Fully balanced by Callies, King main and rod bearings.

|

|

Washing the preservative off of the Callies crank.

|

One rod/piston combo for mock up. |

The rod/piston placed in #1 hole showed good block

clearance...the photo did not "take".

|

Now just a minor delay. The rear main cap gets bound up

a bit by the ARP stud. This causes the crank thrust to be

0.000" Without the cap on the thrust is

.005" I'll have Uncle Randy machine the bolt hole a bit

wider. |

The cap is still prevented from moving

into position because of the main stud. I guess I had Uncle

Randy machine the wrong side of the hole. Well the cap needs

to be able to move forward and it cannot. (see to the right)

But with ARP main bolts the cap can

move into position and the top and bottom bearing thrust surfaces

can align. (see below).

Now the thrust is .006" after

all is said and done.

|

|

|

Thrust is .006 with rear main torqued to 77 ft-lb |

From memory the mains are 2.6484". This is obviously

the 400 SBC size. This is larger than the LT1 small block

Chevy.

|

All mains measured .0030" except the rear main is

.0040" |

Oil galley plug.

|

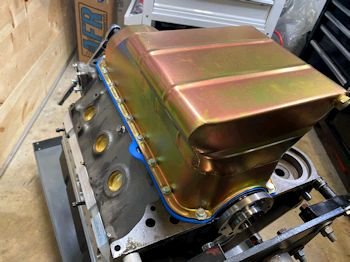

Now waiting on a new oil pan. This one has the dip stick

provision on the passenger side. It needs to be on the

driver's side. |

|

Now installing the proper rear main seal #2909. This one was

supplied by the customer and is for the 2.841" seal bore

diameter. I measured 2.836 at the seal bore and that is

pretty close. This feels tighter than the seal I had in

there and gives me confidence that it will seal. |

Blurry photo: I followed the directions and used this supplied

"shoe-horn" to keep the seal from nicking.

|

3/8" offset and a dab of RTV just like the directions show.

Then I torqued the main cap and re-checked the crank thrust is

still at .005".

Yes I did put the other bearing 1/2 shell in there prior to

installing. :) |

Here is the 8.25" oil pump pickup I ordered.

|

Measures 7.75" off the block. The oil pan is 8.25" deep

and so factor in the oil pan gasket so that gives between

3/8" and 1/2" pickup clearance. |

|

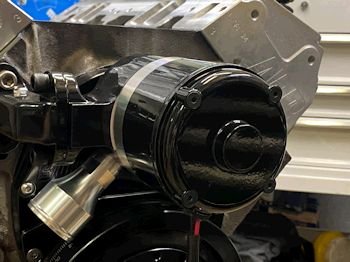

The oil pump is a Melling shark tooth 10554ST with the

3/4" inlet and the pick up is Melling 24360 for 3/4" oil

pump inlet. |

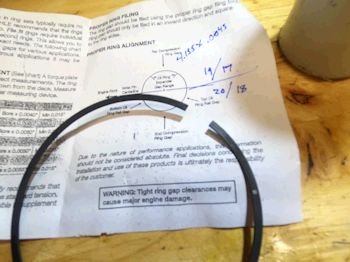

Ring gap calculated for performance street. I am shooting for

.020" top and .018" 2nd ring.

|

Over shot just a bit and I'm at .021" top and .018" 2nd

ring. |

|

Rod bearing clearance at .0022" using King CR807XPN |

Cam design by Dennis Staff. This is from Erson

230/234/106ICL, .584"/.584" lift with 1.6 rockers.

|

Block went to Bill Koustenis (Advanced Automotive Machine in

Waldorf Maryland). He cleaned up the deck in order to allow

me to install MLS head gaskets. He also drilled and tapped

that hole for a clutch pivot. |

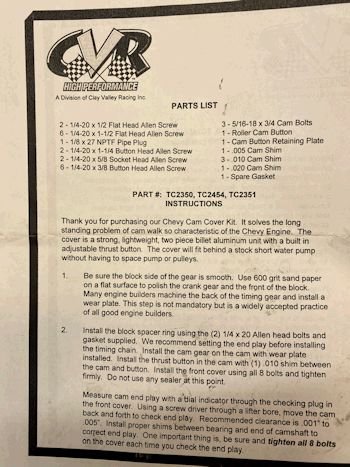

Here is a first attempt at getting proper cam end play.

Spec is .001" to .005".

|

Not shown in the photo but I gave up on the thrust bearing. |

This is the part number for the nice 2-piece timing cover.

|

Instructions for cam end play. |

|

In the end we went with a

nylon button. |

More about the cam button: I trimmed too far again (by

about .005") and so I put a .005" shim behind the

button. It actually worked. Right now the cam end play

is .001". It changed later to zero (after changing the

crank sprocket position to +2*) but I'll tackle that later.

|

So here we are after spending 2 days getting cam end play

right I certainly want to degree the cam shaft again after having

the chain off. In the end the +2* position is the closest to

perfect.. |

Perfect being 106 deg intake centerline. The A2 crank

sprocket position gave 105 deg intake centerline (actually 1 deg

advanced).

|

I etched a circle around the A2 spot for future reference. |

I've had the bolt locking plate on and off a few times you can

see.

|

I thought better of using that plate. I took it off and

now am relying on blue Loctite on the bolts and 20ft-lb |

All pistons in.

|

|

|

Hydraulic lifters blown off with air and soaking in oil. |

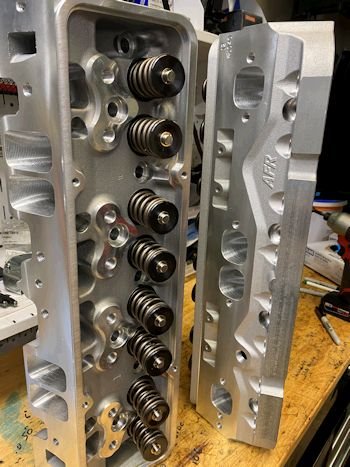

AFR heads

|

|

|

Cometic MLS gasket (.027" thick) |

|

|

Rocker geometry with 7.200" pushrods.

|

|

|

This is the rocker tip sweep with 7.250" pushrods.

I'm happy with this slightly narrower sweep compared to the

7.200" pushrod. I don't want to go to a 7.300 pushrod

and have the rocker too far on the outer edge of the valve

tip. |

Grease on the valve tip and oil on the pushrod.

|

Used ARP head bolts all cleaned up. Up until this point

I only had the passenger side head on. |

Now both heads on and all rockers on.

|

I really like the valve covers. They are on temporary

for dust intrusion prevention. |

Intake manifold on without gasket to check for fit. It

looks good.

|

Just a nice view of the AFR heads. |

Buttoning up the bottom end. Rods are torqued to 75ft-lb

and rod side clearance is .018"

|

Notice the windage tray studs. |

Now they are swapped out with regular sized studs. The dip

stick is on the opposite side for my windage tray that I was going

to install. So the oil pan will have to deal with windage.

|

|

|

Oil pan gasket and oil pan look like a good fit, *by eyeball*. |

|

|

|

<----To the left is the

.005" shim that I put behind this cam button.

|

|

A bit of a story here: I

attempted to verify the cam end play with the timing chain

on. The cam would not move. I believe that the chain

tension prevents that. And so that must be why the

instructions say "measure cam thrust with the timing chain

off". And so I took the chain off and verified cam end

play for the last time. The final result is .0025" to

.003"

Then prior to final installation of the cam sprocket I

squeezed a little bit of grease on the thrust plate and also made

sure the cam seating surface was clean. |

Here the cam nose was wiped clean and verified clean prior to

final assembly. There was some dried up Loktite on it.

|

The cam bolt retainer plate looks a dinged up but the metal is

good quality and soft. |

|

This is the Powerbond neutral balance damper. Good

quality. |

The instructions require a .001" interference and it was

003" (crank diameter 1.246" and hub inside diameter

1.243"). After a few moments of honing the hub is now

1.245".

|

I did not forget to install the cam thrust checking access

plug. |

Here it looks like I'm taking off the damper. I am taking

it back off (not all the way). Turns out the timing cover bolt

cannot be removed with the damper on. I need that bolt for the

timing pointer. The press/pull tool makes it easy.

|

ARP crank bolt torqued to 90ft-lb and then TDC verified and

pointer adjusted. I put the tape on to help me see the left

side of TDC. No timing marks after 5* ATDC because that is where

the PB logo is. The pointer went to 9* BTDC and 9* ATDC with

my piston stop inserted at the spark plug hole for #1 piston. |

I have the Summit #316104 (5") lower radiator hose nozzle

on order. This one is too close to the 8" damper.

|

Darn near complete and ready for the dyno.

To Do:

1. Fuel pump block off plate

2. Water pump 5" nozzle

3. Oil pump spin with drill |

Photo of the flywheel for the SFI record.

|

|

Last view of the heads before I put the intake manifold on.

|

|

|

|

|

First spin of the drill shows 70 psig for oil pressure. |

The lifters sent oil up the pushrod and onto the rockers and

springs.

|

Smoke test of the crankcase (to look for leaks). Only

leak found was where the front two bolts are and at the fuel pump

block-off plate. RTV on the plate gasket and will check

again tomorrow. |

Windage tray time. I should have procured one earlier in

the build. It's not too late. The oil pan gasket is only

RTV'ed to the block corners. The pan came off nicely.

|

I'm choosing the black tray for it's oil shedding coating. |

Back to the windage tray studs. I do them one at a time

and make sure I don't forget to torque them.

|

|

No bending of the tray needed. It fits well. The oil

pan fits over the tray without interference.

|

|

So it looks like if oil is just up to the bottom of the tray

then that is "full".

|

POR-15 Black engine paint. Ready for the engine dyno. |

This will probably work for the dyno but an even longer water

pump nozzle is needed for the future.

|

Neutral flywheel |

Dyno ready.

|

|