|

Billet splayed main cap block freshly machined by Golen Engines.

|

This block has Howard's main caps. Previously I used ProGram

brand main caps but the Chrysler bankruptcy put ProGram out of

business. (Chrysler stiffed 'em on a very large order).

|

|

While waiting on the Advanced Induction TFS cylinder heads and

billet camshaft I decided to move forward and assemble the bottom

end.

|

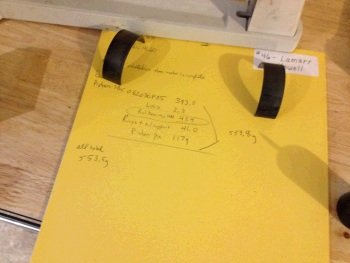

Here is where I weigh each item individually....

|

|

...and then again weigh as a combo.

|

And then compare the results. This time there was less than 1

gram difference.

|

|

Before I send the forged made-in-USA Howard's crankshaft to the

balance shop I mocked up the rotating assembly to see if the rods

clear the block and to see if the bottom of the pistons clear the

crankshaft counterweights.

|

The 1st 396 Mahle piston that exist in an LT1 engine.

|

|

Thanks Mahle for adding this part to your catalog

|

|

|

The bottom of the piston (thankfully) clears the crankshaft.

|

Compstar 6" connecting rod

|

|

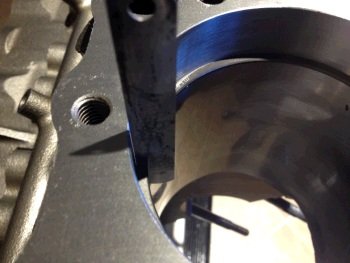

All of the rod bolts clear the block but they are a bit too close.

|

While the crankshaft is at the balance shop I will clear the block a

bit more.

|

|

Crankshaft have been back from the balance shop for ages. Just

waiting on the cylinder heads from Ai right now. Should be

here in a week. Now let's put in some expensive coated

camshaft bearings.

|

Can you see the cam bearing? I cannot. My photography

skills are slipping.

|

|

Measuring for main bearing clearance.

|

|

|

Now filing the rings.

|

Top ring at .022" / 2nd ring at .018". These are

Mahle rings, (1.5mm/1.5mm/3.0mm)

|

|

A few days later here is a good photo of a Callico coated Cam

bearing

|

Main caps #1 (stock) and #2 Howard's Billet.

|

|

Crank thrust at .006"

|

The bottom end before rods/pistons are installed.

|

|

Piston #1 installed and deck-height checked to be -.006" (in

the hole).

|

Rod bearing clearance all at .0020" with Clevite HN (standard).

|

|

|

Ai camshaft Grind: Ai-3442-8HR. A somewhat mildly aggressive street

396LT1 camsahft.

|

|

|

The mostly complete bottom end.

|

|

Rod bolt stretch at .005" (75ft-lb)

|

Don't forget to plug the oil galley. I always take of photo of

the plug for verification.

|

|

|

Sticking with the streetable stock water pump and that calls for a

good stock timing chain upgrade: The Cloyes version of the LT4

Extreme.

|

|

The Cloyes comes with a water pump drive gear upgrade.

|

|

|

Cam card calls for 103.7 deg. intake centerline and I measured 104

with the crank sprocket at "zero".

|

Advanced Induction Cylinder Head Development (Ai CHD).

These are the Trick Flow 215cc LT1 Competition Head. (64cc

chamber).

|

|

The 64cc head, -5cc piston, .039" head gasket, -.006" in

the hole, 3.875" stroke and 4.030" bore equal 11.33 to One

static compression ratio.

|

|

|

Mock up of the Ai heads with the Crower Shaft rockers.

|

This is my new favorite hydraulic lifter. Each and every

lifter is bleed tested by Crower.

|

|

Crower stainless shaft rockers mocked up to test for fit and pushrod

length.

|

I have 7.000" pushrods here and will need 7.100"

|

|

The rocker tips are nicely centered on

the valve tips.

|

Sealing up the ARP head bolts.

|

|

Heads on.

|

|

|

Manley Pushrods

|

Shaft rockers installed.

|

|

Nice view of the sturdy pushrods.

|

|

|

For your viewing pleasure.

|

Test fit of flexplate, (TCI)

|

|

Removing old LT1

|

Bone stock.

|

|

Air pump and all.

|

|

|

|

A good view of the flexplate for future reference.

|

|

|

ARP stainless 12pt timing cover bolts. All motors in the

future will have this nice touch.

|

|

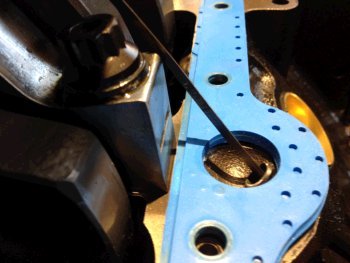

Final details. The oil dip stick should not hit the

crankshaft. I verified.

|

Pay no attention to the cloth fuzz. I removed that.

This shows a bit of a rough way to make sure the stick pokes through

the tray. Due to the splayed cap the stick is diverted a

bit. So I opened up the tray to allow the stick to go where it

wants to. This keeps the stick from hitting the crank.

|

|

|

|

|

|

|

|

Oil system test. All good.

|

EGR delete plate.

|

|

Yank torque converter

|

|

|

Old stock injectors laying on the towel. New Racetronix

37lb/hr high Z injectors in the rail.

|

|

|

The headers are used. They are/were my Grottyohann long

tubes with Swain coating.

|

Right side header? where are you? I'll get photos

later. In the mean time the car needs to head off to the exhaust

shop to have a few transition pipes fabricated. Then off to the

gear shop for 4.11 gear installation.

|