|

Starting off the build on 4-16-07:

Shane is saving a few buck on the crankshaft and rods and spending

it elsewhere on things like coated cam bearings.

Eagle splayed main caps and ARP suds with 3 Milodon studs to hold

stock windage tray. Speed Pro coated main bearings are

installed here

Now the mains are mic'ed.

See results over to the right.

Stopping for the night. Going to find out what timing gear set

will be used and possibly I can put the crank sprocket on to save

Shane the trouble.

Removing all the main caps then lubing the main bearings.

#1 piston on rod. This is for a quick check of piston deck

height, (how far in or out of the hole).

With the rod/piston assembled I can check to see if there is any

interference with the block. I check at the bottom of the

cylinder inboard near the cam and outboard near the oil pan rail.

4-19-07:

Some glitches

Today I assembled the piston-rod pairs.

Eagle 6.0" I-beams. I hate Eagle rods. 2 of the 8

rods had out of spec pin-ends. The piston pin was too tight in

the small end bushing.

Assembly goop on the coated rod bearing.

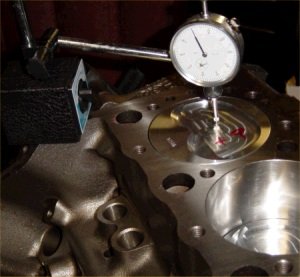

Checking deck height of pistons. I do this

at every corner, (#1, #2, #7, #8 pistons).

That's a .009" out of the hole reading. The pistons are

from .008 to .009" out of the hole. The block was decked

.020" which usually gives zero-deck. Ross pistons are

1.133" compression height instead of the standard 1.125"

(.008" more). This will allow us to select a thick head

gasket while maintaining good quench.

Here is the finished bottom end after having 2 Eagle rods resized at

the pin end. I also clearanced the shoulder of #2 and #6 rods

for cam clearance.

Now on with the stock windage tray. Don't build a motor

without something like this. You'll see low oil pressure at

high rpm if you delete this.

Bend the edges of the tray to fit with the Stef's pan

|

Installing #5 (the rear-most) cam bearing.

Now the galley and freeze plugs. Special tool makes life a bit

easier.

Here are to tools of the trade. Results:

#1 thru #5:

2.4516, 2.4513, 2.4513, 2.4513, 2.4520

All crank journals are 2.4490.

#1 = .026", #2-3-4 = .023", #5 = .030"

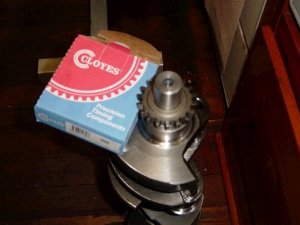

The next night, (4-17-07). Shane lets me put a stock Cloyes

crank sprocket on the crankshaft. While the crank is on the

floor I can hammer it on with a round pipe.

Fuzzy photo of the crank installed with main caps torqued.

A close up of the nice ROSS racing piston with -15cc D-dish and

left/right valve reliefs.

More

tomorrow::

File fitting rings.

Installing all piston/rod assemblies.

Finishing touches.

4-18-07: Taking it slow.

Tonight saw 2 hours of ring file fitting.

Top at .024", 2nd at .028"

Mahle "Blown Gas" specs

More deck height measuring.

Also test fit the stock windage tray onto the Milodon main

studs. I had 2 studs in the wrong spot but that was easy to

correct. The oil pump had to be clearanced a tad to clear the

main cap stud nut. Most of the connecting rods are going to

need clearancing on the big end shoulder to clear the cam.

Tomorrow:

Will have machine shop hone the 2 bad Eagle rods. Will

clearance (remove material from) rod shoulders. Will press on

the oil pump pickup (from STEF's). Will test fit the STEF's

oil pan and make clearance on the pan rail at the usual spot, (at

the rear crankshaft counterweight). Will button up the short

block and wrap for shipping to North Carolina.

Shane's STEF's oil pan arrived today and along with that came the

3/4" oil pump pickup. I hammered it onto the Melling pump

#10551 (HV and HP).

Here is the pan

Short block ready for delivery. 4 bolts holding the Stef's pan

on for transport.

Shrink wrapped and secure.

|